Freedom Paper has added three new inkjet media products for producing full-color photos and posters on in-office aqueous wide-format inkjet printers as well as commercial-use latex and UV inkjet printers.… Read more

The definition of wide-format plotter paper is evolving in today's era of high-volume production inkjet printing. A few things you should know. Read more

Sihl now offers a robust, recyclable, 5-mil multi-layer material for printing two-sided maps, technical drawings, nautical charts, and more. Sihl 6995 Enduro Inkjet 110 Classic consists of a polypropylene film… Read more

In December 2021 the Sihl Group announced the acquisition of Dietzgen Corporation®, a privately held company that provides distribution services for digital print media to the US market. This news… Read more

Users of in-office aqueous-ink wide-format inkjet printers from Canon, HP, and Epson don’t have to outsource all of their projects to a sign shop or print-service provider company. With the… Read more

Buying professional-quality inkjet art paper or inkjet photo paper is different than buying inkjet paper for technical drawings, short-term photographic displays, and everyday office printing. Sometimes, the terms used to… Read more

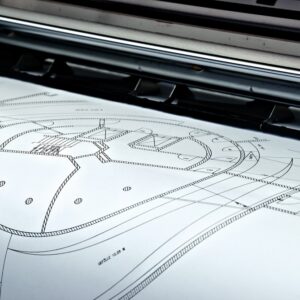

Wide format plotter paper typically refers to the uncoated and coated bond papers that were originally used to make original prints or reproductions of digitally created line drawings. Plotter paper… Read more

Makers of specialty inkjet-printable materials have coated several types of translucent drafting materials, including vellum, mylar, and PET tracing films. You can use these products for markable overlays, mixed-media art… Read more